I was charmed by my first sight of the Barré at the November 2012 Bonhams Auction. The excitement of bidding for the car and at times thinking that it might slip from my grasp remained even as I went to complete the transaction. Even the discovery that due to the value Bonhams management had to authorise my purchase and the frustration of waiting for my bank to authorise payment did nothing to dent my excitement or enthusiasm.

I had noticed at the auction house that the foot brake (transmission) was almost vertical and that the spare tyre fitted on the off side running board interfered with the handbrake. Not a problem I thought until rolling the car out of the trailer on a hill. As car and driver flew backwards at a seemingly higher speed than it had ever travelled before it was fortunate that a rope was still connected. Fortunately, the 4g stop did no damage!

The car had clearly been cared for and a number of modifications, some very novel had been incorporated including plastic armchair type seating, 6volt electric lighting complete with dynamo and cut-out, foot throttle, cam operated ignition and a clutch brake.

The original colour of the car and chassis might have been white with red coach lining, this gave way to chrome yellow and then to the garden green with yellow coach lining, the livery it wore at the auction.

Uncovering the upholstery revealed the original Melton dark navy cloth and vestiges of trim. This material was used as a pattern and the car has been re-trimmed. The period replacement seats are covered in dark navy hide.

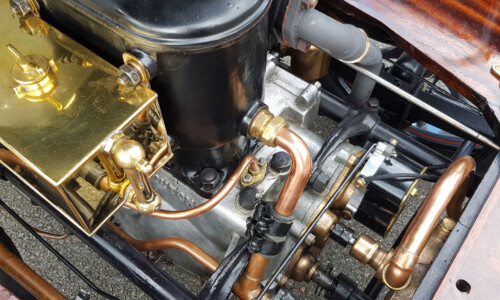

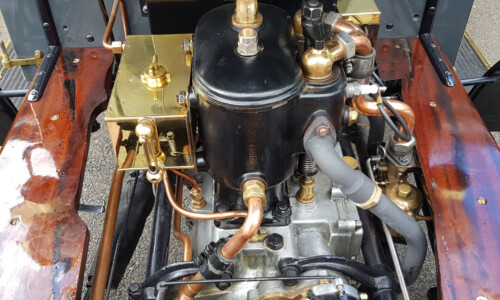

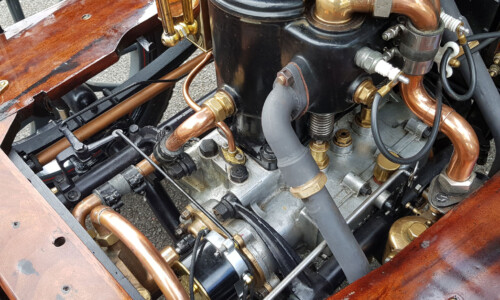

The De Dion 12hp twin cylinder engine is, according to Mr De Dion in the UK, Austin Parkinson, probably the earliest known. It appears that De Dion produced this engine before installing the smaller 10hp version into the vehicles that the company marketed from 1904. The engine was tired and from internal damage to the crankcase there was evidence that something may have gone awry with the decompression system. There is a rod fitted to the cam follower shaft. The two white metal bearings had started to break up, these have been re-metalled as have been the two big end bearings. The original gudgeon pins were secured by bolts fitted in the pistons. The new pistons have floating pins and circlips.. The ovality of the crankshaft was not severe and a minor regrind normalised it. The engine had been resleeved and bored to standard but in an effort to reduce the reciprocating weight and vibration alloy pistons have been fitted. The original cast iron pistons weigh 1.37Kg, the new pistons after a certain amount of fettling weigh 670gm.

I could find no timing marks and with help from Robin Loder and a timing disc downloaded from the internet the exhaust valves open at approximately 37degrees before BDC and close at 18 degrees after TDC. The inlet valves are automatic and open 4mm.

The twin cylinder De Dion engine employs a high capacity oil pump which scavenges oil from the crankcase and replenishes the oil tank which is nicely warmed by its mounting alongside the cylinder block. The oil is fed by gravity through pipes to each main bearing then into drillings in the crankshaft to the big ends. I would imagine that oil control was a problem in early engines as there were deflector shields at the base of the bores and the pistons held five broad compression rings,

The original ignition system used a clever single blade operated by a desmodromic make and break arrangement. Later engines adopted two blades and were more reliable. This system was missing from my car although parts of the original cover remained. I have made a copy of an original mounting plate and repaired the cover. The internals are electronic and triggered by magnet. The system works with accuracy and reliably.

The planetary gears in the differential were very badly damaged and have been replaced. The differential carrier and rear wheels are supported by cup and cone bearings, the cups have been reground and the balls replaced. The drive from the clutch through the first motion shaft to the rear wheels is entirely by square shaft. This system does cause a certain amount of backlash and easily explains the adoption of splined shafts when engineering facilities permitted.

The road springs had sagged causing the chassis to rest upon the front axle. The shackle pins were modified coach bolts and have been replaced, the springs have been bronze bushed and front and rear springs have been reset by a local blacksmith.

The water tank had been repaired so many times it became more viable to replace it using the original as pattern. The closing plate for the water tank is unusually placed at the left hand side of the tank rather than at the bottom. From a wear mark on the flywheel it would appear that a friction drive water pump might have been fitted at some time, however when offered for sale a Di Dion water pump had been fitted and which was driven by chain. Because the alignment was not perfect and there was no information regarding the earlier pump, I have refitted the pump in front of the engine and it is now driven by a coupling from an idler gear within the timing gear chest.

There were fragments of what I believe to have been the original the exhaust system remaining and a new system using the cast iron fittings that came with the car has been made. The silencer of the absorption type i e. straight tube drilled with numerous holes and wrapped in a heat proof sound absorbent material. I believe that the original silencer may have held baffles but none remained.

Twin cylinder engines fitted to De Dion cars were originally fitted with a twin choke carburettor arrangement. I do not know what my car would have been fitted with but I believe that the long inlet pipes that passed to the front and rear of the cylinder block and dropping down to a position at the base of the engine might have been fed with this type of carburettor. My car had been fitted with a pair of Solex 26mm MOV carburettors. From cars that I have seen the very long inlet pipes have been wound with small bore copper tubing that is heated from the water system. Because I intend using the car and do not know the original fitment I have adopted a single 30mm Solex MOV carburettor. The fuel tank is impossible to completely de-silt and a fuel filter is in place I may remake the fuel tank when time permits.

The front axle and king pins are all suspended by cup and cone bearings. Unfortunately the king pin ball bearings had ‘hammered’ the cups and the steering juddered as the steering was turned. The lower bearings have been changed for taper roller but the top cup and cone have been reground and retained.

There was evidence that the bearings to the front wheels had not been correctly adjusted and the near side axle had been badly damaged, new axles have been fitted and a combination of sealed ball-race and the original cup and cone bearings used.

Strangely a number of components of the front axle were nickel plated. I have found it difficult to obtain any history of the car but one enquiry indicated that the car was imported by the Belgium importer of De Dion cars and for his own use. It is possible that the car may have been shown on a stand at a motor show of the time. Investigations continue.

Because I was unable to provide sufficient evidence of date of original manufacture it took almost two years before a registration number could be issued by the DVLA and my thanks to the care and diligence of Chris and Margaret Rolph of the dating committee is gratefully acknowledged.

I have been fortunate in being able to employ Vicky Pont of Hooe in East Sussex for so skilfully and thoroughly stripping, preparing, painting and coach lining and finally varnishing the car and wheels in a traditional manner.

In accomplishing the restoration of the Barrè I have benefitted from the services and help of:-

Front axles and steering ball, Nick Wright of Halland, Crankshaft regrind and white metal bearings, John Kirkby of Croydon, Craftmaster Paints, Leather supplies, Leonard Stevens, Old Town Eastbourne, Differential pinions, GN Roper Rochester, Bearings cone track regrinding, GP Precision Grinders, Wokingham, Metal forming, Rod Yeates of Vines Cross, East Sussex, Radiator and water tank, Lloyd Brian,Tunbridge Wells, Road spring resetting by Tivoli Forge of Hastings, Leatherwork and trim, Simon Barringer, Birmingham, Hood and extraneous trim by Vicky Pont, Hooe, electronic ignition by Minimag, Isle of Wight and finally, for castings Harling Metal Foundry of Hastings.

Michael Kent